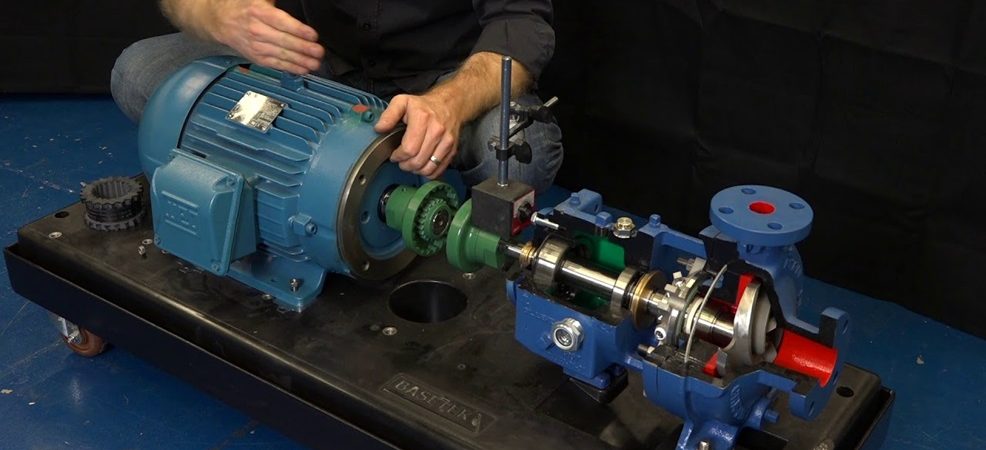

Regular maintenance and upkeep, as well as ensuring that the machinery is kept greased and efficient pump alignment, are all important parts of keeping equipment functioning smoothly. The risk of costly, unplanned machine downtime increases considerably when shafts or belts on spinning machinery are misaligned. Seals and couplings are also harmed by misalignment. Seals that have been weakened by shaft or belt misalignment are frequently the source of lubrication issues. Replacing a seal will not prevent future seal failure and lubricant loss; only fixing the misalignment will resolve the issue.

Misalignment Of The Shaft

Shaft misalignment accounts for up to half of all expenditures associated with rotating machinery breakdowns. Accurate shaft alignment can prevent many machinery malfunctions and decrease most of the unscheduled downtime that leads to production loss. The importance of correct shaft alignment has never been stronger in today’s challenging environment of cost reduction and asset optimization.

Proper Alignment

In both the horizontal and vertical planes, machines must be aligned. Therefore, parallel or angular misalignment, or a mix of both, can cause misalignment.

- Misalignment can be divided into two types: parallel (or offset) misalignment and angular misalignment. The center lines of both shafts run parallel to one another. However, they are offset in parallel misalignment. The shafts run at an angle to one another in angular misalignment.

If these issues are not addressed, a system may have various issues, including early pump or motor failure. Shaft misalignment can also cause a pump’s early wear of the seal, packing, shaft, and bearings. This can result in excessive leakage, vibration and noise, poor efficiency, and higher power and maintenance costs for the system.

METHODS FOR PUMP ALIGNMENT

Traditional visual methods or the laser approach can both be used to align thepump. Strings and/or straightedges are commonly used in traditional procedures. However, a laser beam is used in laser techniques, providing significantly better accuracy.

A laser belt alignment system allows for far faster and more precise alignment adjustments than traditional methods. The manner the gadgets are mounted to the pulley and how they align can be used to categorize the systems on the market. In general, there are two groups: one that aligns the pulleys’ faces and another that aligns the pulleys’ grooves.

A laser belt alignment system allows for far faster and more precise alignment adjustments than traditional methods. The manner the gadgets are mounted to the pulley and how they align can be used to categorize the systems on the market. In general, there are two groups: one that aligns the pulleys’ faces and another that aligns the pulleys’ grooves.

The face or side of the pulley is used as a reference for aligning the pulleys and belts in most items on the market. This approach can apply to belt types other than V-belts, such as timing belts. On the other hand, V-belts make up the bulk of belts on the market, particularly in industrial applications.

PROPER ALIGNMENT MUST BE MAINTAINED

Following the detection, analysis, and correction of misalignment, a continuing alignment maintenance program is required to keep operations running properly. Alignment checks should be undertaken as part of this maintenance to document alignment conditions before a machine is removed from service. This allows users to install new or rebuilt machines with the same accurate alignment values. A maintenance schedule should also include frequent tests to ensure that conditions remain within acceptable limits.

Why You Should Choose Us

Regardless of the thickness, brand, or kind of pulleys, products that align using the grooves of the pulleys in which the belt passes tend to deliver significantly higher levels of precision.

Fortunately, laser alignment devices are far more effective than other common technologies at creating efficient and streamlined vertical and horizontal pump shaft alignment. Our team at BENCHMARK PDM has the expertise you need to thrive as the master distributor of Easy-Laser in Canada!

Contact us immediately for a laser alignment system rental or servicing quotation!